Blacktop Repair: Strategies for Prolonging Road Life

Introduction

While our streets, highways, and parking lots are designed to withstand the constant onslaught of traffic and weather, they’re also heavily dependent on blacktop repair. Blacktop is commonly used for road construction because of its durability, but factors such as traffic, weather, and poor drainage erode the material over time. Without proper maintenance, simple cracks and potholes can lead to unsafe driving conditions and costly repaving projects. In this blog, we’ll discuss the leading causes of blacktop damage and the best blacktop repair strategies for prolonging road life.

Understanding Blacktop

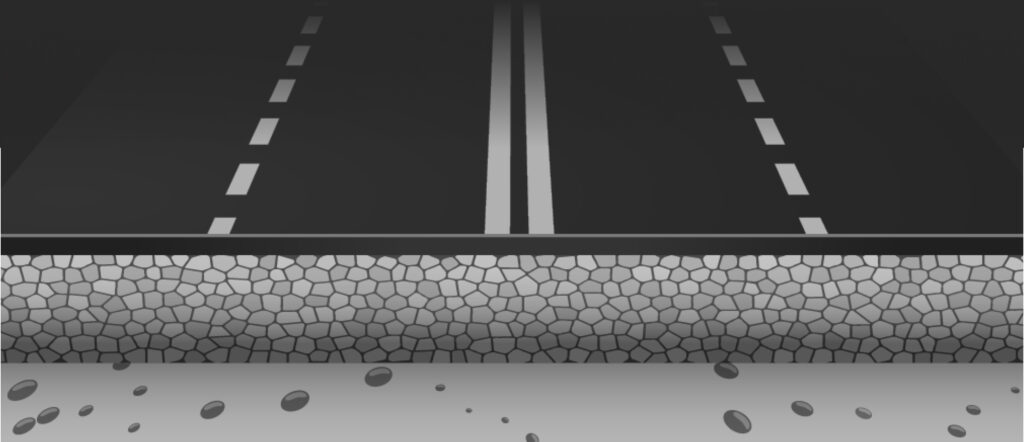

Blacktop, otherwise known as asphalt, is a mixture of stone aggregates and bitumen primarily used in the construction industry for roads and roofing. Despite blacktop’s seemingly simple composition, this material is manufactured in a variety of forms ranging from hot to cold mixes and recycled to natural materials. Each mixture having its own intended usage and application.

Regarding road construction, the process of laying or repairing blacktop involves compacting the material onto a solid, prepared base. Once fully bonded, blacktop provides a smooth and durable surface for vehicular and pedestrian traffic. This bond is largely dependent on the mixture. One of the most commons forms of blacktop, hot mix, hardens after cooling to ambient temperatures. Materials such as cold mix rely on chemical reactions from their liquid binders to create a bond. Natural blacktop repairs, such as RockAsphalt©, relies solely on compaction to form an immediate, permanent bond.

The sleek black appearance of blacktop provides a clean and polished look to any surface while also offering excellent traction for vehicles and pedestrians. Its ability to withstand factors such as heavy traffic loads, harsh weather conditions, and temperature fluctuations makes it a preferred option for road repairs and construction projects. However, these factors are also the leading causes of blacktop repair.

Common Causes of Damage

While blacktop’s superior durability provides a stable and safe driving surface, it inevitably falls into disrepair. The most common causes of blacktop repair are heavy traffic, weather, poor drainage, and aging.

Traffic Loads

Traffic can significantly damage blacktop due to the constant pressure and weight of vehicles passing over the surface. The repetitive stress caused by cars, trucks, and buses can lead to the development of cracks, potholes, and other forms of deterioration. As vehicles accelerate, brake, and turn on the blacktop, the friction and heat generated can weaken the asphalt binder, making it more susceptible to wear and tear.

Additionally, environmental factors such as sunlight, water, and temperature fluctuations can worsen the damage caused by traffic, further compromising the integrity of the blacktop surface over time. Regular blacktop repair is essential to preserving the longevity and functionality of roads under the relentless stress of daily traffic.

Weather/Poor Drainage

Weather is also a key stressor that causes damage. The constant exposure to sunlight causes the blacktop to oxidize and become brittle, leading to cracks and potholes. When water seeps into these openings and freezes during colder temperatures, it expands, further widening the cracks. The freeze-thaw cycle exacerbates the damage by weakening the structure of the blacktop. Additionally, heavy rainfall can erode the base underneath the blacktop, leading to sinkholes and uneven surfaces. Overall, the combination of sunlight, water, and temperature fluctuations can deteriorate blacktop surfaces, necessitating regular maintenance to prevent further damage.

Poor drainage can wreak havoc on blacktop surfaces, leading to extensive damage over time. When water is not properly diverted away from the blacktop, it can seep into cracks and crevices, weakening the structure from within. Like the freeze-thaw cycle, this trapped water freezes in colder temperatures, causing the blacktop to expand and crack further. Additionally, prolonged exposure to standing water can degrade the integrity of the blacktop, leading to potholes, rutting, and overall deterioration. Effective drainage systems are crucial in preserving the longevity and quality of blacktop surfaces, preventing costly repairs and ensuring safer driving conditions.

Aging

Aging inevitably takes its toll on all blacktop surfaces, as time and weather conditions gradually deteriorate the once-smooth and resilient material. The culmination of harsh weather and heavy traffic lead to the oxidation and drying out of blacktop, causing the pavement to lose its flexibility and strength. Over time, even roads paved with the highest quality materials and workmanship will require repair.

Blacktop Repair Strategies

Choosing the Right Blacktop Repair Method

When it comes to selecting the appropriate repair method for blacktop surfaces, several factors must be considered. The extent and type of damage plays a crucial role in determining the most suitable approach. Minor, surface level cracks can be repaired using a simple crack filler or by sealcoating the surface. More extensive damage such as resurfacing, or pothole patching will require a quality blacktop repair product.

Weather conditions and traffic levels must also be considered. Heated blacktop repair materials are regarded for their durability but have strict weather requirements limiting when they can be applied. Products such as cold mix, while used to repair blacktop in inclement weather, may be unable to withstand the amount of pressure in high-traffic areas. RockAsphalt© combines the durability of hot mix with the all-weather reliability of cold mix, making permanent blacktop repairs possible year-round. Ultimately, choosing the right blacktop repair method comes down to circumstance.

Preventive Maintenance

Preventive maintenance for blacktop surfaces is crucial to ensure longevity and optimal performance. Regular inspections for cracks, potholes, and surface wear are essential to address minor issues before they escalate. Scheduled seal coating can provide an added layer of protection against water penetration and UV damage, extending the life of the blacktop.

Sweeping debris regularly and keeping drainage systems clear can prevent water pooling, which is a common cause of deterioration. Implementing a proactive maintenance plan for blacktop surfaces not only enhances their durability but also minimizes the need for expensive repairs down the line.

The Importance of Quality Materials and Proper Application

When considering blacktop repair, the importance of quality materials and proper application cannot be overstated. Utilizing high-grade materials, like RockAsphalt©, ensures durability and longevity of the repair, protecting the surface from deterioration due to weather elements and heavy traffic. Additionally, blacktop repairs made with RockAsphalt© are protected by our 3-year guarantee.

Proper application is also crucial for achieving a high-quality blacktop repair. Failing to apply the material correctly can result in issues such as uneven surfaces and water pooling. When this happens, further damage can lead to failed patches and rework. By investing in superior materials and skilled labor, blacktop repair can not only look good but save time, money, and eliminate rework.

Blacktop Repairs for Prolonging Road Life

Blacktop surfaces are bombarded with daily traffic, bad weather, poor drainage, and the passing of time. Eventually, every surface will require some form of repair. By choosing the best quality blacktop repair for your project, employing preventative maintenance strategies and proper application, you can significantly improve the condition of your blacktop surfaces. Ultimately, adhering to these strategies not only enhances the appearance of blacktop but also helps extend its lifespan, saving time and resources in the long run.

Ready to do road repairs the fast & easy way?

RockAsphalt© replaces cold and hot mix making road repair of all sizes fast, clean, simple and permanent the first time.

Try it for yourself and learn why crews love it.

Get your free sample bags and have your team see how fast and easy it is to permanently fix potholes.